Modula’s Biotech Tower: A New Era in Vertical Farming

Meeting the Pressures of Modern Farming

Today’s agriculture is under pressure to produce more with fewer resources. Land is limited, energy efficiency is essential, and demands for food safety, crop consistency, and traceability are increasing. Modula has responded to this challenge with the Biotech Tower, a fully automated vertical farming system designed for the evolving needs of modern farming.

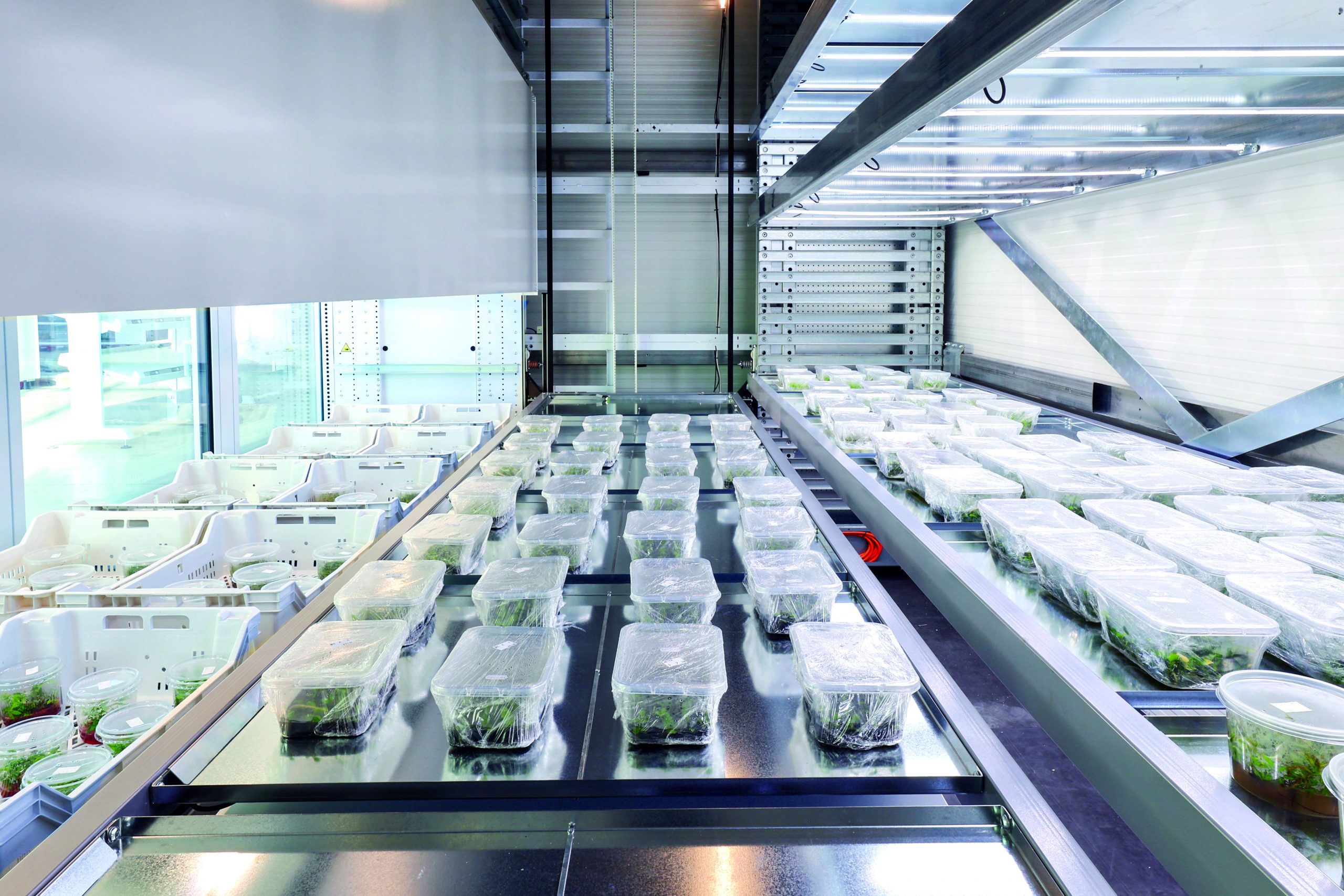

Originally developed for industrial logistics, Modula has adapted automation technology to serve the agricultural sector. The Biotech Tower introduces a highly controlled, scalable solution for micropropagation, automated vertical farming, and plant research. It reflects a clear shift toward compact, intelligent, and sustainable cultivation systems.

Automated Vertical Farming Built for Control and Precision

The Biotech Tower is engineered to maintain precise control over environmental variables including lighting, humidity, temperature, carbon dioxide, and fertigation. Environmental parameters can be tailored to the needs of each crop, with temperature settings between 18°C and 28°C, humidity from 40% to 90%, and CO₂ levels up to 2000 ppm.

Its sealed structure protects crops from contamination and eliminates exposure to external fluctuations. Moreover each unit can be divided into climate-controlled zones, further enhancing precision and flexibility.

Initially tested with strawberries, basil, lettuce, and chili peppers, the system demonstrated its ability to deliver reliable, high-quality results. According to expert agronomists involved in the pilot phase, the greatest success came in micropropagation, where exact conditions and sterile environments are critical to plant development and genetic consistency.

Delivering Clear and Measurable Advantages

The Biotech Tower is more than a growing chamber. It is a smart, integrated production system that offers a range of tangible benefits:

- Maximized Use of Space: The unit’s vertical design enables efficient use of cubic volume. A unit measuring 33 feet in height can handle between 250,000 and 500,000 seedlings while using up to 90% less floor space than a traditional greenhouse.

- Reduced Contamination Risk: Each stage of the production cycle takes place in a closed, insulated space. Operators work through sealed access bays, and the system undergoes regular ozone cleaning to maintain sterile conditions.

- Greater Energy Efficiency: With reduced reliance on traditional HVAC systems, energy consumption is significantly lower. Daily costs average between $22 and $27, and optimized lighting reduces illumination energy usage by up to 50%.

- Higher Yields and Shorter Cycles: By maintaining stable conditions, the system promotes uniform growth and reduces waste. Crop yields can increase by 25%, and production cycles can be completed up to one week faster than standard methods.

- Full Traceability and Live Monitoring: Every tray and container are digitally tracked and monitored in real time. Operators can identify plant locations, review environmental data, and intervene when needed, creating a transparent and repeatable process.

Expanding the System Beyond Micropropagation

While the Biotech Tower is ideally suited for in vitro plant production, its design is flexible enough to support other applications. These include:

- Mushroom cultivation

- Insect protein farming

- Seed selection and testing

- Controlled-environment nursery operations

All these benefit from the same core capabilities: reliable environmental control, reduced contamination risk, and process standardization. With the addition of Modula Climate Control modules, the Biotech Tower becomes part of a broader ecosystem

A Practical Vision for the Future of Vertical Farming

The Biotech Tower introduces a new model for agricultural production. It supports precision, improves consistency, and enables cultivation in locations where land and climate present limitations. For both large-scale producers and specialized research facilities, this automated vertical farming system offers a clean, efficient, and scalable solution.

Adopting this technology is not only a technical decision. It also requires a shift in mindset, embracing innovation as a long-term investment in sustainability and productivity.

Industry Outlook and Growth Potential

Vertical farming is no longer a niche concept. It is rapidly emerging as a transformative solution for sustainable agriculture. According to Grand View Research, the global vertical farming market is valued at $8.15 billion in 2024 and is projected to reach $24.95 billion by 2030, growing at a CAGR of 20.9 percent. Key factors driving this growth include the need for efficient land and water usage, year-round crop production, and increased urban food demand. However, the industry also faces challenges related to energy consumption, high upfront costs, and limited crop diversity for profitability. Despite these hurdles, ongoing innovations in LED lighting, automation, and AI are steadily improving the economic and environmental viability of vertical farming.

Redefine Farming with the Power of Vertical Precision

Explore the Technology

As vertical farming becomes a key part of the global agricultural landscape, solutions like the Modula Biotech Tower offer a clear path forward. Whether used for micropropagation, research, or controlled-environment food production, Modula’s technology enables higher productivity, greater control, and long-term sustainability.

To learn more about how automated technology fits into your agricultural strategy, visit our product page or contact us for details.