Vertical Lift Modules

Boost productivity and accuracy, increase storage capacity, and enhance worker safety

Vertical Lift Modules Benefits

Available in a wide range of sizes and capacities, Modula VLMs are the ideal storage solution for any operational need

Recover Valuable Floor Space

Recover floor space

Maximize payload capacity

Experience flexibility

Gain full control with our WMS

Grow, reposition, scale

Utilize a sustainable solution

Boost Your Productivity & Accuracy

Save time

Increase accuracy

Improve inventory management

Easy software integration

Control access

Prepare for tomorrow

Designed with Worker Ergonomics & Safety in Mind

Lower stress and strain

Simple and intuitive solutions

Higher productivity

Safety and ergonomics

Redefine job descriptions

Easy learning curve to operate

Vertical Lift Modules Benefits

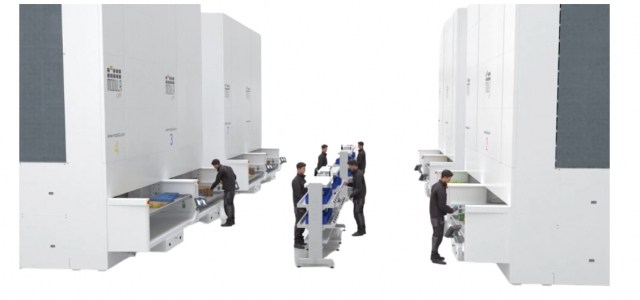

Maximize performance across your entire manufacturing floor space with Modula Vertical Lift Modules

300 lines per hour

140 trays/hour

Tray payload capacity of

up to 2,299 lbs

0.98” / 25MM

or dual delivery bay

27.36” – 35.23” – 50.98”

10.4” touch screen operator console

easy to learn

66 inch / 1.6 m depth

Touch Screen Interface

between trays

unbalanced loads

190 trays/hr

Tray load capacity of up to

772 jbs

240V three-phase

48-V three-phase

Warehouse Efficiency:Manual vs. Automated Warehouses

Breaking down Key differences across labor, speed, cost, and more

A large amount of wasted space, of the warehouse layout.

Optimal Space utilization

Up to 90% floor space saved.

Man-to-goods

Operators need to walk and search for items. All process are manual 60 to 80 picks/hour.

Goods-to-man

Manual processes are automated. No more time wasted searching for items. 250 to 350 pick/hour.

High labor-intensive tasks, such as loading and unloading, picking and packing.

Up to 85% more productivity

One worker can handle the equivalent of 3-4 manual pickers.

Manual picking is prone to errors, mispicks and inaccurate data.

Up to 99% more accuracy

thanks to simple and visual picking aids, designed for error-free picking.

Workers need to climb, reach, bend, and lift to retrieve parts. High risk of safety hazards.

Items are delivered to the worker at the ergonomic picking height. Less fatigue, and risk of injury.

Products are not protected and can be accessed by anyone. No locks or restricted access.

Products are protected through automated tracking and controlled access.

Tracking inventory relies on manual checks or record-keeping, which can be time-consuming and prone to errors.

Real-time visibility of inventory through integrated software. Instant access to inventory levels, locations & movement.

Not suitable for large, delicate or high-value items, due to space and manual handling limitations.

Secure solution for a wide range of products, including bulk, fragile, high-value, and climate-sensitive items.

Limited scalability to changing product demands or new order fulfillment models.

Easy scalability to meet changes in product demand and as business grows.

Get a Free Assessment

Get in touch with our technical specialists

Discover all Modula VLM Models

Modula VLMs are the ideal storage solution for any operational need

Modula Lift

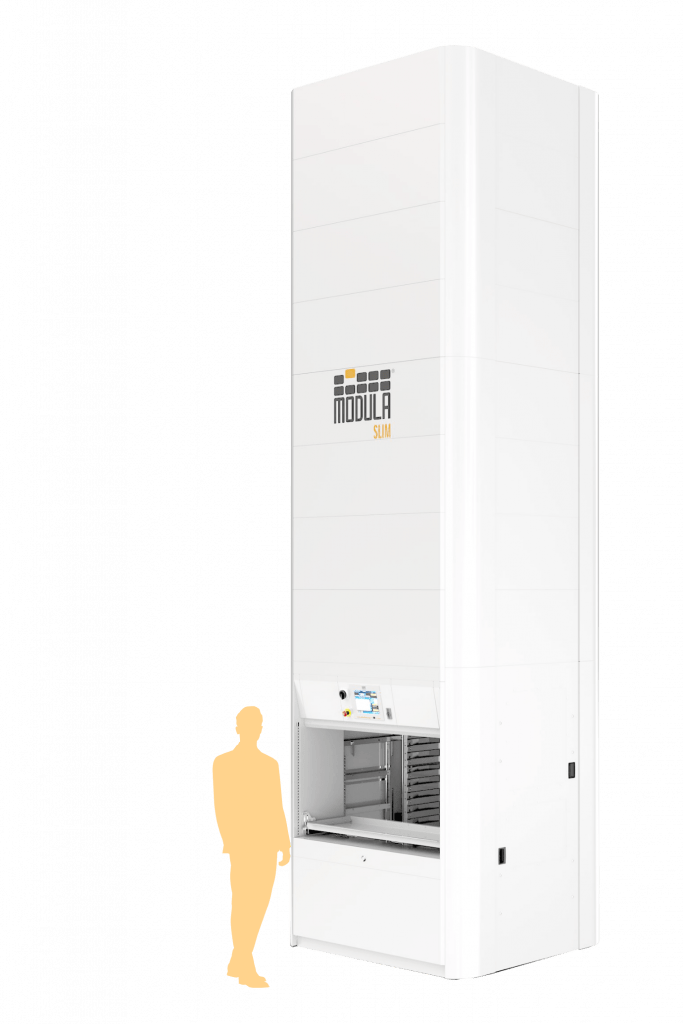

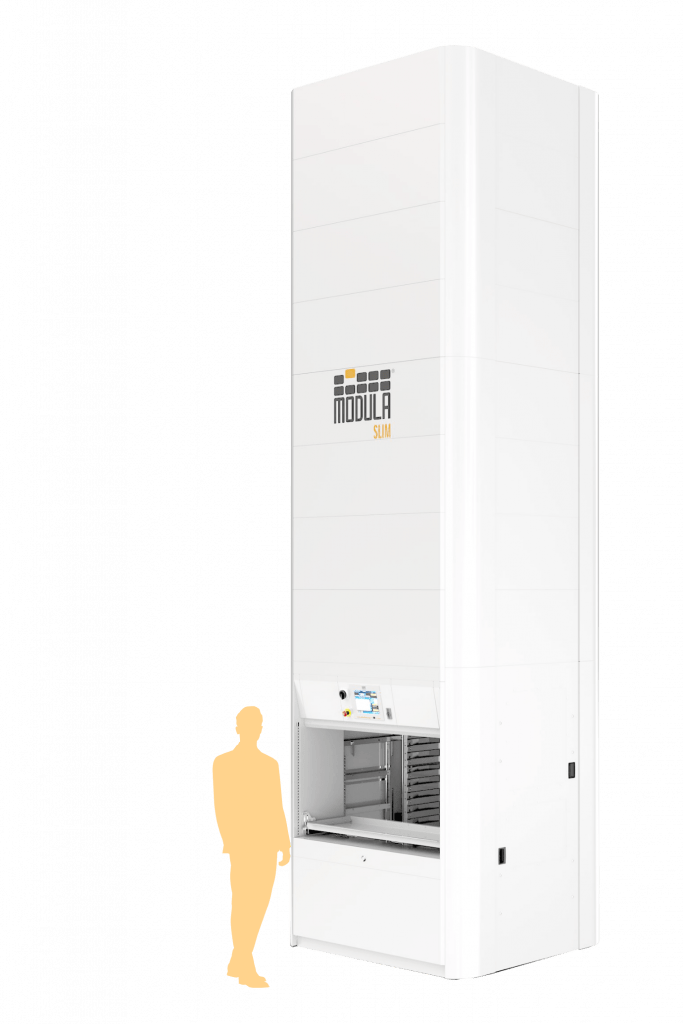

Modula Slim