Benefits of Automotive Parts Shelving Systems

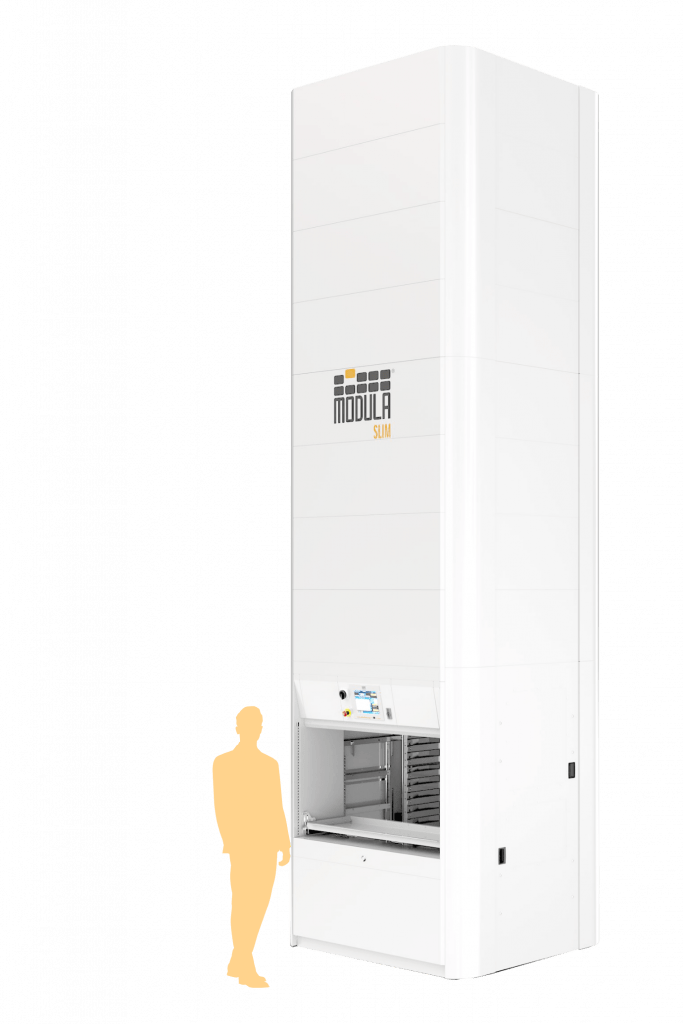

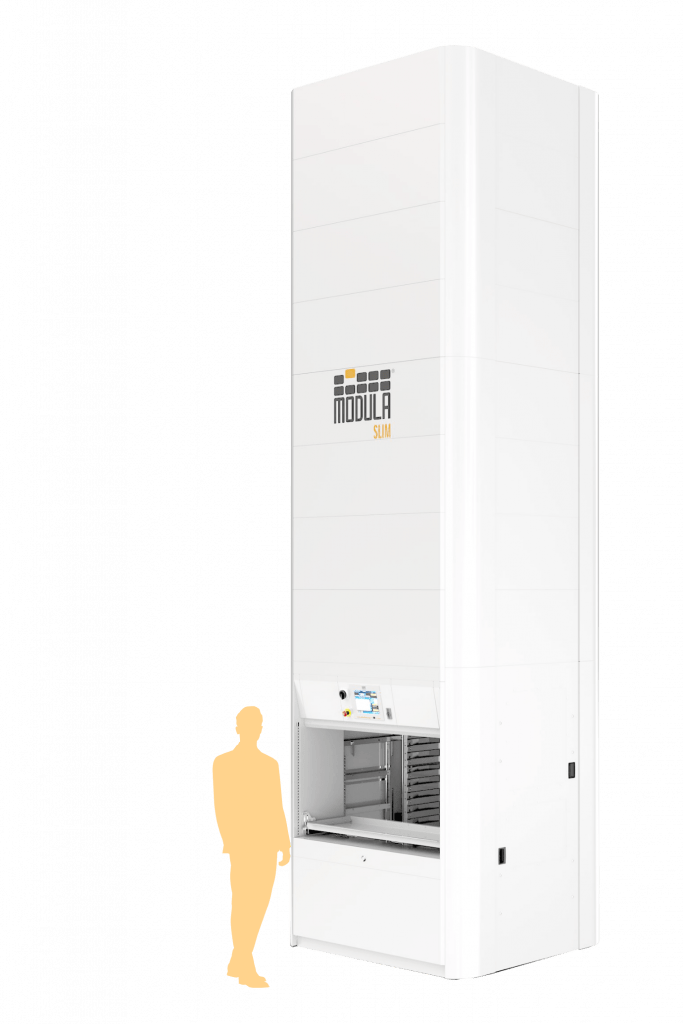

With multiple sizes and capacities to choose from, Modula’s automotive parts shelving systems provide adaptable storage for any facility.

Create space for new service bays, offices, or customer areas

Repurpose floor space

Maximize capacity

Organize efficiently

Control operations

Boost Your Productivity & Accuracy

Save time

Increase accuracy

Secure inventory

Scale sustainably.

Ergonomic, safe, and easy for everyone to use

Work comfortably and safely

Refocus on what matters

Train faster

Paperless workflow

Our Case Study

Subaru of New England, Norwood (MA)

Auto Parts Distributor, Subaru of New England manages over 9,000 parts in just 896 sq.ft and achieves throughput rates of 1,600 lines a day.

BMW of Wichita, Wichita (KS)

Walser BMW cuts warehouse space 85% and improved organization by storing components, from windshield wipers to flexible pipes, in Modula units

Earnhardt Lexus, Phoenix (AZ)

Earnhardt Lexus stores over 1,000 components only 10 ft from the parts counter, allowing employee to retrieve more than a third of the parts with just a short walk.

Walser Car Reconditioning Center, Eagan (MN)

With a single VLM, Walser Car Reconditioning Center stores 200,000 auto parts in just 154 sq.ft, improving productivity and inventory tracking.

Pacific Coast Heavy Duty Truck Group, BC, Canada

Pacific Coast Heavy Duty Truck Group, authorized Volvo subsidiary, saves 80% of storage space for small boxes and the spare parts with Modula units.

Ford Motor, Almussafes, Spain

With three VLMs equipped with robotic arms, Ford Motor optimizes its manufacturing, allowing the factory to run on a six-day-a-week cycle and produce 17,250 engines per week.

The advantage of the Dealer Management System (DMS) integration

Get a Free Assessment

Get in touch with our technical specialists

Automotive Industry Clients we Also Serve

Accuride Wheel End Solution

Allison Transmission

American Axle & Manufacturing

Audi

American Showa

Autovega

Benteler

Bentley Motors Ltd

BMW

Bosch

Brembo

Bridgestone

Caterpillar

Chapman Trucking

Charter Automotive

Chevrolet

Contitech

Chrysler

Continental

Daimler

Dana Automotive

Ducati

Earnhardt Lexus

Ferrari

Ford

GKN Driveline

Goodyear

Kia

Harley Davidson

Honda

Hyundai

Hurley Chrysler Jeep

Jaguar

Lamborghini

Luther Cadillac

Kirchhoff Automotive Aurora

Mack Truck

Mercedes

Maserati

Meritor Inc

Michelin

Mitsubishi

Mubea

Paccar Engine Company

Pacific Coast Heavy Truck Group

Peugeot-Citroen

Polaris

Porsche

Renault

Robert Bosch

Rolls-Royce Motor

Seat

Subaru

Suzuki America

Tenneco Automotive

Tesla

Titan Motorsports

Tower Automotive

Toyota

TRW Automotive

Valeo

Volkswagen

Volvo

Voss Automotive

Walser Automotive Group

Wendle Nissan

Woodhouse Mazda

Zeromax

Discover all Modula VLM Models

Modula VLMs are the ideal storage solution for any operational need

Modula Lift

Modula Slim