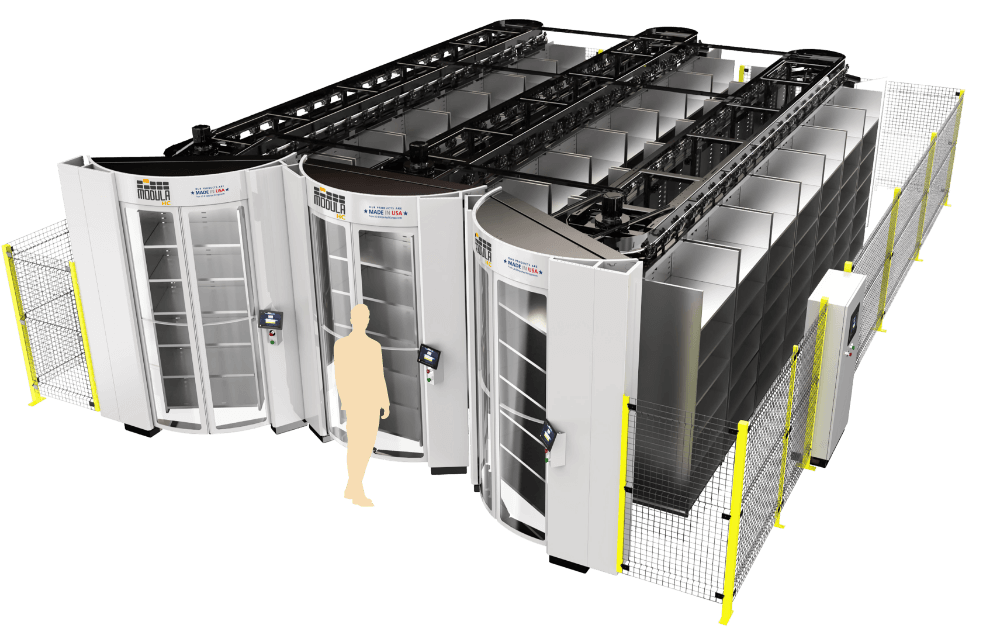

Modula Shelving Systems for Automotive Parts

Modula Automated Storage and Retrieval Systems Are Trusted By:

Benefits of the Modula Auto Parts Storage Solution

Maximized Space

Optimized Inventory

Improved Picking Accuracy

Increased Operational Safety

Control operations

Purchase a USA-Made Product

Our Case Study

Subaru of New England, Norwood (MA)

Auto Parts Distributor, Subaru of New England manages over 9,000 parts in just 896 sq.ft and achieves throughput rates of 1,600 lines a day.

BMW of Wichita, Wichita (KS)

Walser BMW cuts warehouse space 85% and improved organization by storing components, from windshield wipers to flexible pipes, in Modula units

Earnhardt Lexus, Phoenix (AZ)

Earnhardt Lexus stores over 1,000 components only 10 ft from the parts counter, allowing employee to retrieve more than a third of the parts with just a short walk.

Walser Car Reconditioning Center, Eagan (MN)

With a single VLM, Walser Car Reconditioning Center stores 200,000 auto parts in just 154 sq.ft, improving productivity and inventory tracking.

Pacific Coast Heavy Duty Truck Group, BC, Canada

Pacific Coast Heavy Duty Truck Group, authorized Volvo subsidiary, saves 80% of storage space for small boxes and the spare parts with Modula units.

Ford Motor, Almussafes, Spain

With three VLMs equipped with robotic arms, Ford Motor optimizes its manufacturing, allowing the factory to run on a six-day-a-week cycle and produce 17,250 engines per week.

The advantage of the Dealer Management System (DMS) integration